When myenergi unveiled its zappi GLO EV charger earlier this year, it wasn’t just a leap forward in smart home energy tech – it was a bold statement in sustainable innovation.

Engineered from the ground up with eco-conscious design at its core, GLO delivers a 35% reduction in embodied carbon compared to its predecessor, zappi 2.1; proof that performance and environmental responsibility can go hand in hand. Indeed, for every 1,000 units manufactured, the CO₂ saved is equivalent to driving over 157,000 km in an average UK car – enough to travel from London to Sydney and back twice.

We spoke with Emma Brigginshaw, Head of Sustainability at myenergi, to gain an exclusive insight into the role of sustainability in the company’s new product development process. We delved deeper into the brand’s material use, recyclability, and energy efficiency in its environmental considerations.

The obvious question first, then, Emma. How important is sustainability to a leading global technology brand?

“In short, it’s fundamental. myenergi is a business born from a desire to have a positive impact on people and the planet. Our products and services are deliberately designed with sustainability at their core, enabling our customers to decarbonise their lives.

“When it comes to manufacturing our eco-smart product range, we’re committed to protecting, sustaining and enhancing vital natural resources that will be needed in the future, achieving growth while considering the true cost of doing business.”

How is sustainability viewed within myenergi’s new product development process?

“Our product delivery lifecycle prioritises sustainability. Specific objectives are set and agreed, ensuring their consideration throughout specification, product design, sourcing, packaging and even software optimisation.

“But we don’t stop there. Our circularity model keeps sustainability front-of-mind throughout the whole product lifecycle, helping to ensure efficient manufacturing processes, minimal distribution impacts and working on closing the loop at product end of life.”

What about the specifics of GLO? How did the R&D team tackle material use during the design process, for example?

“When it came to designing the physical aspects of zappi GLO, we prioritised material and component optimisation. Unlike many other chargers in the marketplace, all external parts are made from a single, recyclable material.

“We also designed a new plug to remove the need for two material types, as well as eliminating the need to bond parts to the plastic housing. Overall, plastic use has been reduced by 30%.”

What other design innovations were used and how do they stack up from a sustainability perspective?

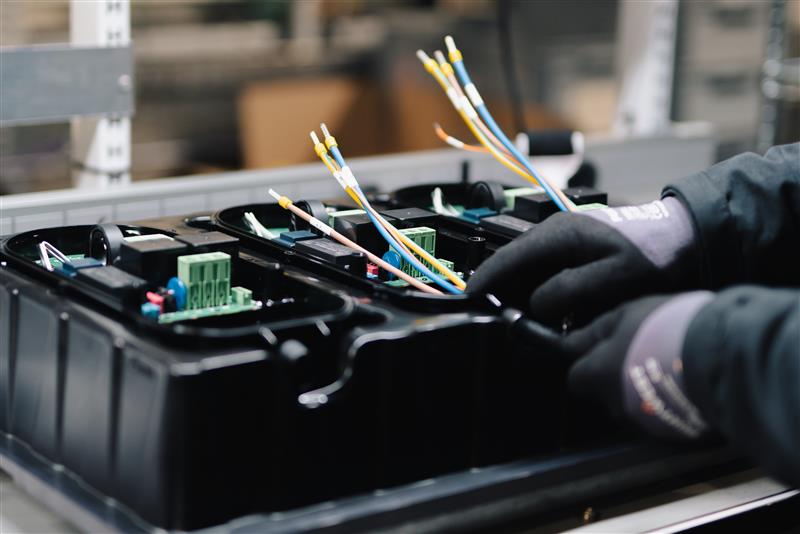

“A major step forward was reducing the number of printed circuit boards (PCBs) needed to control the device. Rather than six separate boards, GLO boasts a single PCB, which lowers weight by 30% (from 0.68kg to 0.46kg) and reduces PCB surface area by 64%.

“Elsewhere, further improvements have reduced firmware size by 30% and telemetry data volume by 33%. Collectively, this contributes to lower embedded and operational energy use.”

Impressive stats, but what about energy efficiency? How does the device perform in this respect?

“GLO demonstrates incremental improvements across the board – and energy efficiency is no different. For example, the device maintains the same idle consumption but reduces maximum power draw by 30%.

“In simple terms, this significantly improves overall energy efficiency when the device is idling – a simple way to further improve environmental credentials.”

Are there any other areas where innovation has helped to streamline environmental impact?

“By building accessible testing points into the PCB, we’ve ultimately enabled automated testing. As a result, we’ve been able to improve production efficiency without increasing energy use – a big step forward that delivers more units per kWh.”

When you consider that myenergi is already a sustainability pace setter in the marketplace, GLO’s impact against other charging devices becomes evident. It’s clear that the team have invested heavily in pushing boundaries and moving the needle.

Importantly, however, its sustainability credentials are backed up with advanced features and functionality. With out-of-the-box energy tariff integration and automated solar compatibility as standard, the screenless, buttonless single-phase device offers effortless integrated charging. Controlled via the myenergi app, users have the option to simply plug-and-go, or explore toggle options to adjust settings, set timers, monitor performance and optimise device performance in real-time.

What’s more, zappi GLO forms part of myenergi’s home energy management system (HEMS), an integrated network of eco-smart solutions that ensures households are given total control over their energy use, alongside the flexibility to switch to the best smart tariff. Alongside the eddi solar diverter, this includes the libbi home battery and harvi wireless monitor.

For more information about myenergi and its award-winning zappi EV charger, visit www.myenergi.com.